Fugitive Emissions Technology

98% Less Emissions Than Traditional Globe Valves

Typically called “volatile organic compounds” or VOC’s, common greenhouse gases like methane (CH4) and other compounds have become an increasingly real threat when licensed to operate. With industries worldwide trying to maneuver new guidelines to meet the goal of net zero by 2050, it is more important than ever to utilize our data, experience, and technology modernization to reach climate progress.

An estimated 64% of man-made global warming is caused by CO2, while methane, found to be as much as 26x as potent, is responsible for 17%.

The concentration of CO2 in the atmosphere has climbed from 280 PPM to 409 PPM since the industrial revolution. With methane being 26x more powerful than CO2 as a greenhouse gas, 100 PPM of methane is equal to 2600 PPM of CO2 equivalent. The U.S. Environmental Protection Agency (EPA) states that 60% of all fugitive emissions derive from valves, and up to 80% of this leakage is found in the stem-seal interface. The best option available for a low emissions globe valve currently measures leakage at 100 PPM, allowing the valve to continue contributing to the already growing concentration of CO2 in the atmosphere.

Since the passing of the Clean Air Act Amendment (CAAA) in 1990, designed by the EPA to curb major environmental threats like toxic air emissions, many worldwide endeavors have been made to lower industrial fugitive emissions. Despite these efforts, reducing fugitive emissions remains one of the most challenging hurdles that the valve industry faces today.

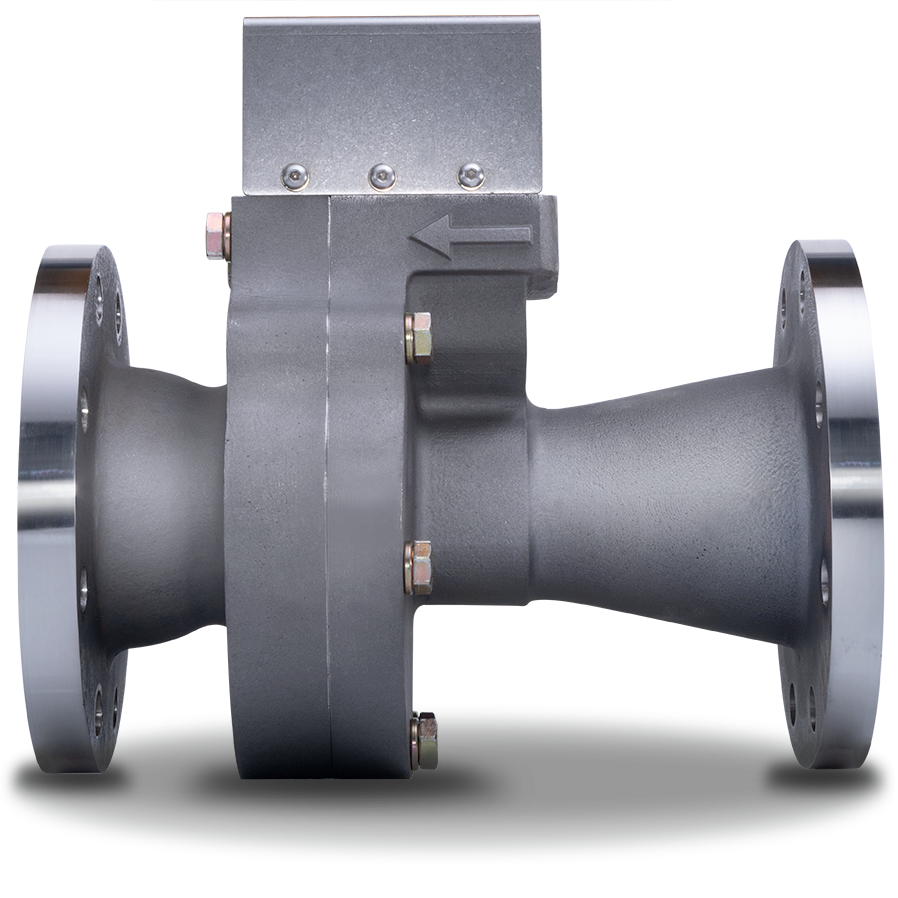

Manufactured in Rhode Island, Clarke Valve’s Dilating Disk™ Valve records a methane leakage rate of only 2 parts-per-million (PPM) under the ISO 15848-1 standard, compared to around 500ppm recorded in conventional globe valves. This makes the Dilating Disk™ Valve the ideal control valve solution to dramatically reduce fugitive emissions. In addition to virtually eliminating fugitive emissions, the Dilating Disk™ Valve requires less torque to open and close, making it more energy efficient when running, and allowing the valves to be powered by off-grid renewables in some cases.

To better serve partners and customers in the Oil and Gas industry while fulfilling the company’s goals to play a role in climate progress, Clarke Valve engineered the Dilating Disk™ Valve to reduce emissions in the stem-seal interface with a patented series of stem seals. The unique, near-zero leakage technology of Clarke Valve control valves is available for as low as 50% of the price of competitors’ “low-emissions” control valves. Clarke Valves are API 641 and ISO 15848-1 certified to reduce emissions up to 98% and have been tested in the field to prove that emissions are typically eliminated entirely to 0ppm.

Previously, near-zero leakage in an operating valve has only ever been achievable with a bellows seal, which can be very costly and complex to maneuver when maintenance is required. The unique and patented stem-seal technology of the Dilating Disk™ Valve has made zero-leakage possible within a simplified and affordable system.