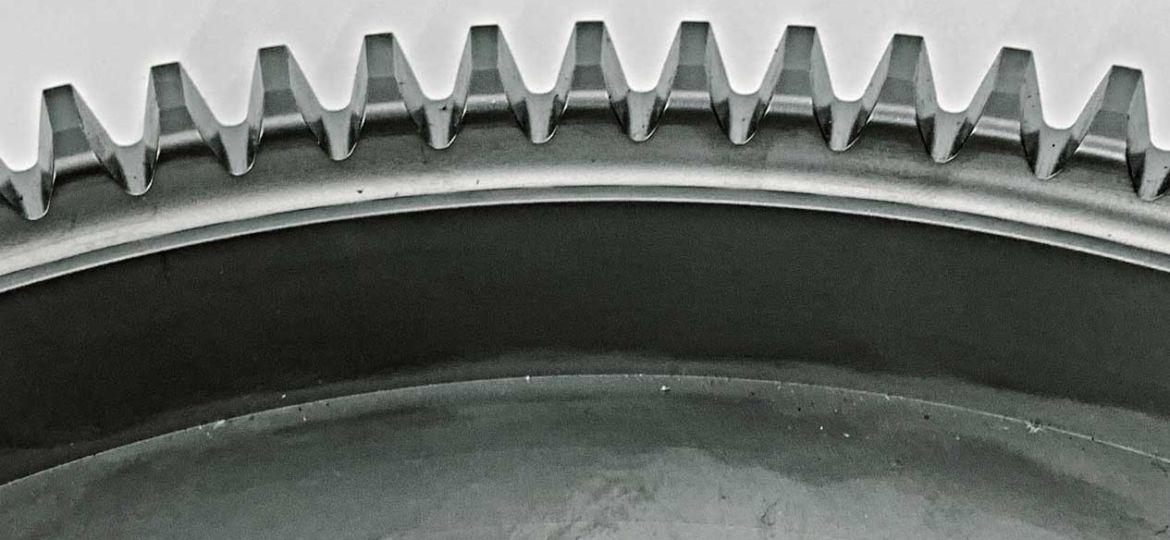

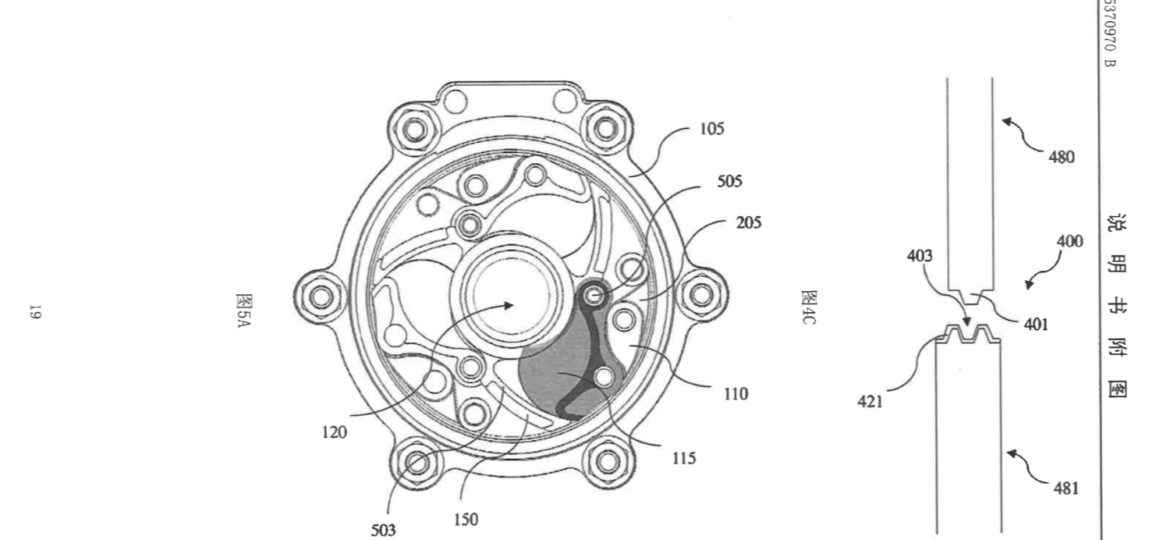

Clarke Valve, a portfolio company of Saudi Aramco Energy Ventures, Chevron Technology Ventures, and OGCI Climate Investments, announced today that it has expanded its growing collection of global patents. The National Intellectual Property Administration for the People’s Republic of China…

Blog

The world’s most compact, efficient, and environmentally responsible control valve has achieved yet another performance benchmark, completing over 100,000 mechanical cycles while consistently surpassing the most stringent standard for fugitive methane emissions.

In his presentation, Kyle Daniels describes the Dilating Disk™ Valve and its fugitive emissions reducing capabilities, as part of an overview of Clarke Valve and the venture investment provided by the Oil and Gas Climate Initiative (OGCI).

The Dilating Disk™ Valve has earned another certification for fugitive emissions reduction, meeting the standards for ISO 15848-1:2015 in testing earlier this week…

Clarke Valve announced that it has secured European Patent Office (EPO) protection for its proprietary Dilating Disk™ Valve technology…

Clarke Valve shared its story of methane emissions reduction with visitors to…

Clarke Valve has taken steps to accelerate its future growth, on-boarding several new team members…

Clarke Valve today completed the sale of $5.5 million of Series B Preferred Stock to a group of investors led by OGCI Climate Investments. Along with funding from Saudi Aramco Energy Ventures and Chevron Technology Ventures, Clarke has now raised $15.5 million of Series B funding.

Clarke Valve announces ISO 9001:2015 certification as it expands in-house manufacturing capabilities. ISO 9001 is a quality management standard that provides tools and guidance for companies to ensure their products and services consistently meet customer requirements, and that quality is consistently improved.

Clarke Valve announces the API 641 certification of its proprietary Dilating Disk™ Valve design, the first control valve to achieve this certification of low fugitive-emission performance.

The API 641 standard applies to all stem seal materials and requires a stringent maximum allowable leakage of 100 parts per million by volume (PPMv). This API test standard calls for 610 cycles of the valve under extreme temperature fluctuations to evaluate emissions performance over an accelerated life cycle.