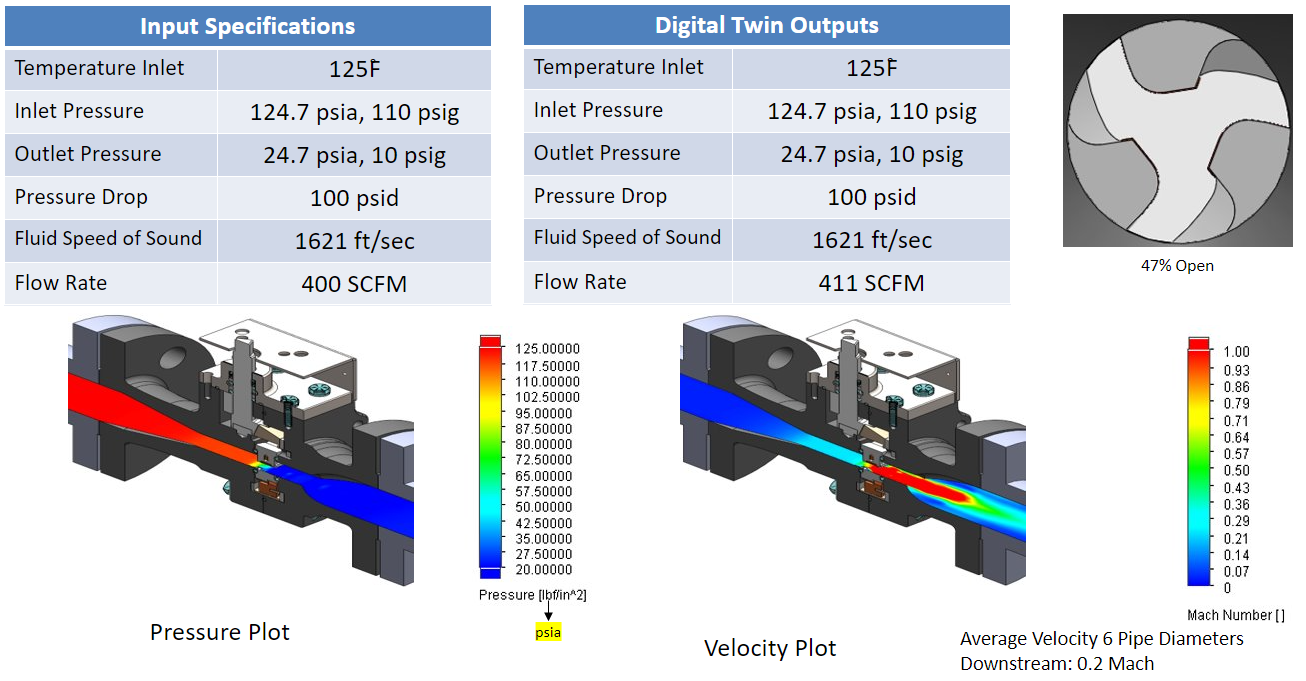

With the advent of Digital Twinning, operating companies no longer need to run the risk of introducing a flow element into their process without total confidence in its process and reliability performance.

Clarke Valve, the exclusive manufacturer of the revolutionary Dilating Disk™ Valve, uses Digital Twinning to ensure optimal operational and reliability performance for each process application before each unit is completed and ready for installation.

What is a Digital Twin?

Digital twinning, or the creation of a virtual replica of a product and the process conditions under which it will operate, allows manufacturers to analyze data and optimize their products before they are placed in service. Thereby allowing manufacturers to analyze data before physically creating a product. This virtually eliminates the risk of adverse effects on downstream equipment and/or downtime after the valve is in operation.

Digital Twinning and the Dilating Disk™ Valve

NASA, one of Clarke Valve’s customers, was one of the earliest adopters of the concept of Digital Twinning. This makes it only more fitting that the Dilating Disk™ Valve, which was created with aerospace design principles in mind, would use this same concept to simulate precision flow control.

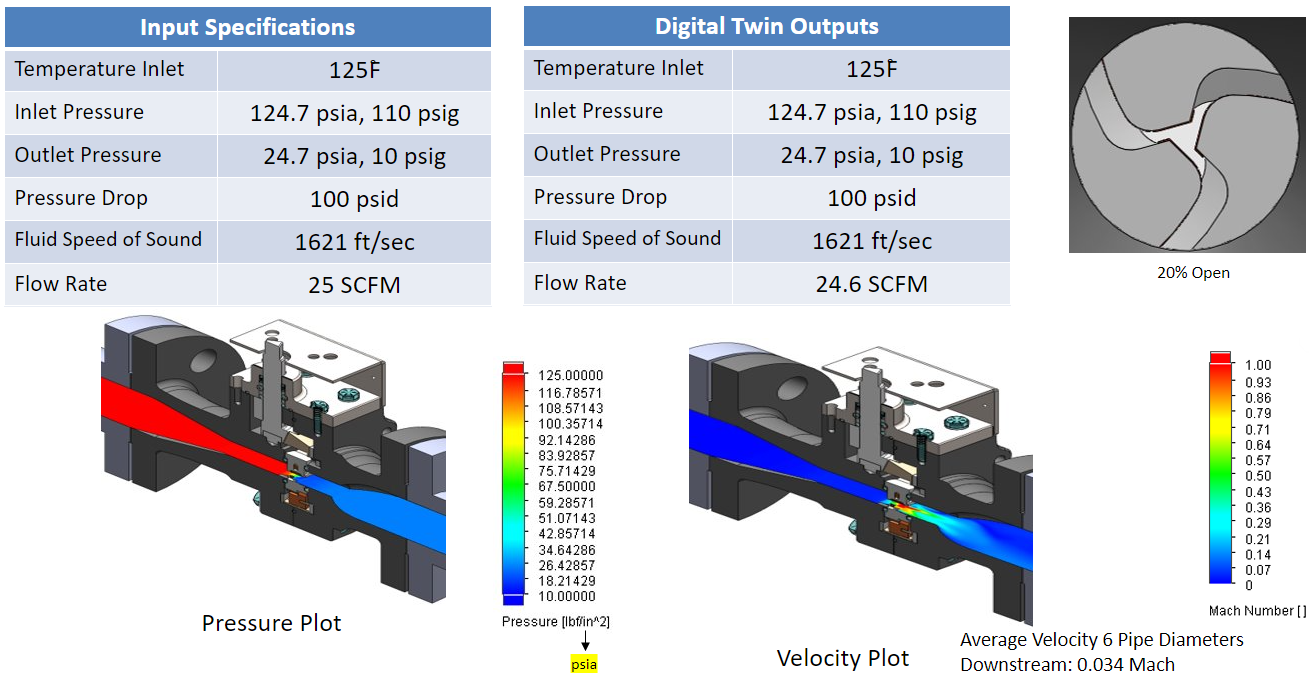

With the help of Computational Fluid Dynamics (CFD) simulations, a Digital Twin of each Dilating Disk™ Valve is created by in-house engineers, so that the Clarke Valve team and their customers have the ability to simulate performance and data before deploying their product. The engineering team at Clarke Valve reviews the simulation flow rates, pressure drops, and other fluid dynamic parameters. Evaluating these parameters alongside the customer allows Clarke Valve to optimize the valve before it is built. These simulations are a small fraction of the cost of deploying a less than optimal flow control valve.

Digital Twin technology allows for more predictive maintenance, making it the perfect tool to ensure reliability in high-yield assets. When a Clarke Valve customer is looking for a Dilating Disk™ Valve for their application, some of the specifications that they will send to the team include the upstream and downstream pressures of the process fluid as well as the flowrate. The simulation of the valve shows the process fluid flowing through the pipe and the opening of the valve, demonstrating the flow capacity and characteristics of the product. By creating a Digital Twin of this valve, and showing the product working in a virtual environment, customers can see if the valve sizing is correct for the specifications of their application. This process helps customers to see if there is any cavitation of flashing present in the system. The capability to visualize potential high velocity areas helps both Clarke and the customer prevent damaging fluid structure interactions, all while increasing the longevity of the equipment. Gathering this data from a Digital Twin ahead of installation ensures that the facility using this new valve can maximize their operation time and reduce any downtime that they may have had to otherwise use for unplanned maintenance.

Ahead of the Curve

“As the tools at our disposal become more sophisticated, we must also push ourselves to change our approach to problem solving. It is not enough to have access to the tools; we must also use them in their entirety as an industry to keep pushing the boundary of digitization forward. Without the right outlook, the technology only exists, lying idle.”

-Catherine LeBoeuf, Clarke Valve Lead Engineer

While Digital Twinning may not be a new concept, it is rapidly gaining momentum across several industries. According to IDC, it is projected that 70% of manufacturers will be using this technology to collect data and conduct simulations by 2022, allowing them to reduce equipment failures by 30%. As the Clarke Valve team continues to build Digital Twins for each valve requested, we are eager to continue to produce dependable results for each customer, while further developing prototypes and products through simulation and virtual testing.